New technology makes lab food safety testing faster and more precise

By Lilian Schaer for Bioenterprise Canada

A Stoney Creek company has developed a technology that can standardize and automate lab sampling needed for food safety testing.

“We create tools that help labs extract samples in a way that is suitable for testing – and by automating the process, we ensure consistency, better quality and precision, and traceability,” explains Farouk Saleh, president of Merq Incorporated, whose main focus is on food and food safety.

Although some food producers have their own in-house laboratories, most companies use the services of third-party labs. Merq’s goal has been developing a standardized, off-the-shelf solution that it can provide to both in-house and third-party test labs.

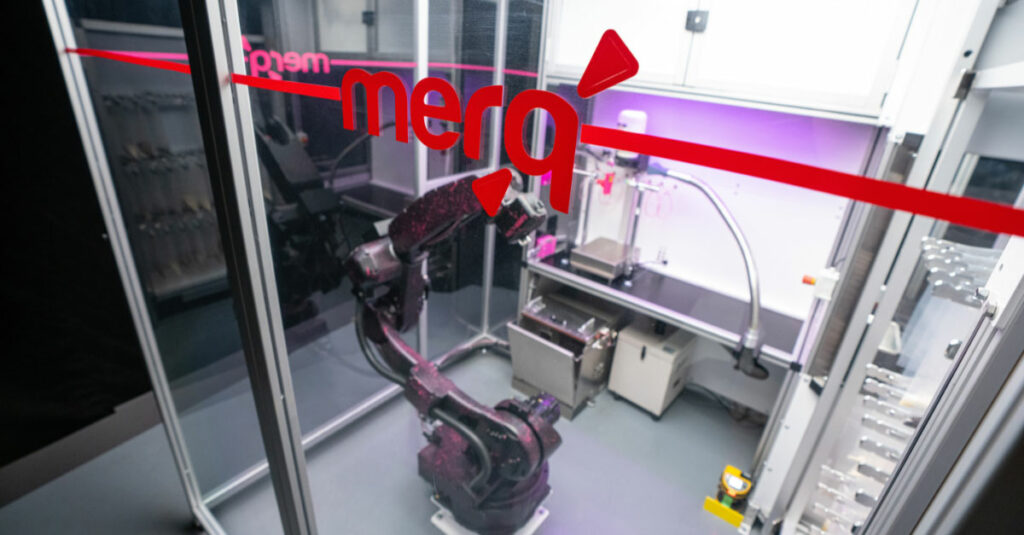

Merq received support from the SmartGrowth Program, which is funded by a Government of Canada investment of over $6 million, through the Federal Economic Development Agency for Southern Ontario (FedDev Ontario), and administered by Bioenterprise Canada. The program helped the company complete the development of an automation system called the SuperNova, which incorporates tasks like sample handling, temperature control and chemical dispensing into a single, contained system that will handle all of it automatically for the lab.

“Currently, food labs rely on very semi-automated processes, which means they use machines but with a lot of human intervention. With SuperNova, we’ve taken the approach of full automation,” Saleh says.

Merq was well into developing the system when it applied to the SmartGrowth program. The non-repayable funding it received helped the company set up the machine at one of Canada’s largest third-party food testing labs and run a three-month pilot project. This let the team study its performance, calculate real return on investment with the client and integrate improvements they suggested based on working with the system in a real commercial setting.

Merq also used some of the funding to take SuperNova to the International Association for Food Protection trade show to get it in front of potential customers and highlight its functionalities.

“The pilot project was so successful that the client ended up buying the machine. We’re a small company so that is a big deal for us,” he says. “This helped us validate the technology, and we made a big splash at the trade show where we were able to connect with some big labs in the United States. We’re now working on quite a few deals because of that.”

According to Saleh, a key learning from the trade show experience was that while smaller labs need solutions, they don’t necessarily need a full-scale machine. Earlier this year, Merq released a modular machine that now makes the different subsystems available to these smaller labs. SuperNova also enables downstream automation, and Merq is now working on several solutions to support those activities.

“For us, this funding was tremendous. We are a small organization that is self-funded, and I don’t think we would have had the funds to even attend the trade show. None of this would have happened, especially not on the timeline we had,” he says.

An added benefit of the SmartGrowth funding was being able to work with the Bioenterprise Canada team, who have provided valuable introductions, made networking connections for marketing support and are helping with business strategy development.

“As a small business owner, working with the team at Bioenterprise has been really terrific. They made the project administration easy so we could execute and move quickly with our project, and although it’s still early days, they’ve helped us with some potentially very significant networking opportunities,” Saleh adds. “What they do is very impressive.”

Learn more about Merq Incorporated

Learn more about Bioenterprise’s SmartGrowth Program

Learn more about FedDev Ontario

-30-

Follow Bioenterprise on social media or subscribe to our channels for the latest industry news, events, and business development opportunities.