Using food waste to grow more food

Montreal’s first mushroom farm benefits from Bioenterprise Canada support

For Dominique Lynch-Gauthier and Lysiane Roy Maheu, the amount of food waste they were seeing in Montreal was concerning. At the same time, the mushroom lovers lamented how difficult it was to buy fresh, local and high-quality mushrooms in the city.

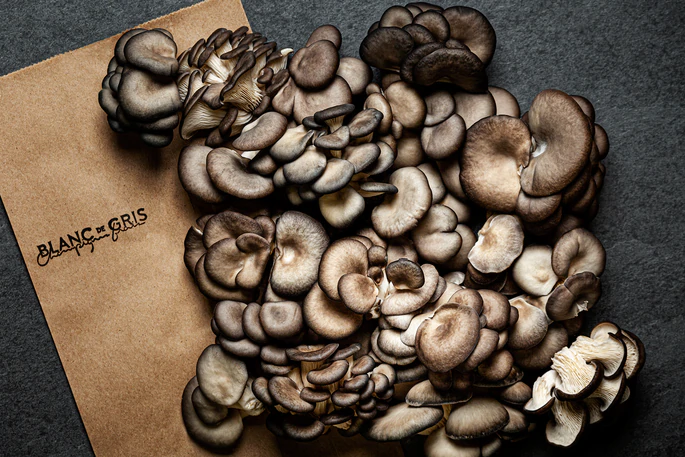

When they realized that it was possible to grow mushrooms using food by-products, the two lifelong friends decided to get into business together – and Blanc de Gris was born. They are Montreal’s first mushroom farm, growing oyster mushrooms in substrates – the material mushrooms grow in – that they make by repurposing waste products.

This includes grain leftover after beer brewing by local microbreweries, coffee chaff from local coffee roasters, and even sawdust from a local furniture business. Their mushrooms are grown in reusable buckets instead of single use plastic bags and are sold primarily to high end restaurants in Montreal.

“From the beginning, the circular economy was at the heart of our mission. When I realized that I could grow mushrooms and lower food waste at the same time, I thought this would make a wonderful business project – and when I started to get more information about it, I realized that there is a growing market in Canada for mushrooms,” says Lynch-Gauthier.

Blanc de Gris chose to grow oyster mushrooms because they are easier to grow than other types of mushrooms and adapt the best to a variety of different substrates, she added.

An upcoming expansion will involve a move to a bigger location with more automation and continuing to improve their mushroom-growing process, but they also want to manufacture and sell their unique substrate.

The plan is to locate a substrate production facility right next to a microbrewery, which would eliminate the need to pick up the spent grains, which spoil quickly if they’re not used at the right time, several times a week.

It was while doing research for their expansion that Lynch-Gauthier discovered Quebec’s ZoneAgTech and their partner Bioenterprise, Canada’s Food & Agri-Tech Engine. She’s part of the Cycle Momentum Agtech Acceleration Program, which is run by ZoneAgTech, an incubator in the Montreal area that supports innovation-focused start-ups and entrepreneurs, and a member of the Engine.

Through the accelerator, Lynch-Gauthier participated in a variety of workshops, from marketing and communications to pitching and finding funding, and received valuable business support from a mentor.

“Since I participated in this program, I am a better entrepreneur; it’s been very helpful. And my mentor had experience in mushroom growing so he was able to give me ideas on how to improve yield and lower my costs,” she says. “This has helped me make a better product and improve my value proposition.”

As Canada’s Food & Agri-Tech Engine, Bioenterprise Canada brings more than 15 years of industry experience and a national and international network of research institutions, academia, mentors and experts, funders and investors, government, and industry partners to help small and medium-sized businesses in the agri-food sector nationwide connect, innovate, and grow.

For more information about ZoneAgTech and other Bioenterprise Canada funding and accelerator programs, visit https://bioenterprise.ca/programs/.

-30-

Not yet following us on social media? Follow Bioenterprise on Twitter, LinkedIn, TikTok, and subscribe to our YouTube channel for industry news, events, and business development opportunities.